Industrial embroidery machine TMAR-KC

The cylinder type TMAR-KC II Tajima range, representing the latest in innovation by Tajima Europe, has now arrived. It is the embodiment of Tajima technology for highly efficient production, the highest quality, robustness and unparalleled performance.

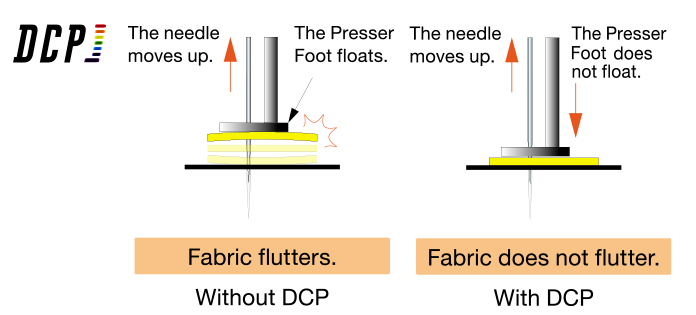

To craft embroidery down to the finest detail, TMAR-KC II boasts an innovative system known as the ‘DCP feature’ with the inclusion of a presser foot which is controlled digitally from a tactile control panel and whichenables users to adjust the position from bottom dead centre as well as the strength of each needle to be adjusted independently.

The stitching strength is thereby configured in accordance with the type of material, which ensures there is no movement of the material and this leads to considerably fewer thread breaks when starting the machine. The independent presser foot allows for ultra-precise embroidery on materials such as leather, thick or very fine and even delicate fabrics, layered materials and embroidery with foam for a 3D effect on caps.

The precision of needle penetration has been increased by 60% and this ensures a very neat finish even for detailed embroidery.

The development of another feature, called ‘fine stitch mode’, reduces the tension on the thread, which can be very useful if you use particularly challenging threads such as twisted or very thick thread. You’ll feel as though you’ve produced hand-made or lace style products.

The tighter cylinder arm facilitates embroidery on finished goods such as pockets or sleeves. The reinforced cap frame combines a stable production of your embroideries with a potential rotation speed of 1,000 rpm.

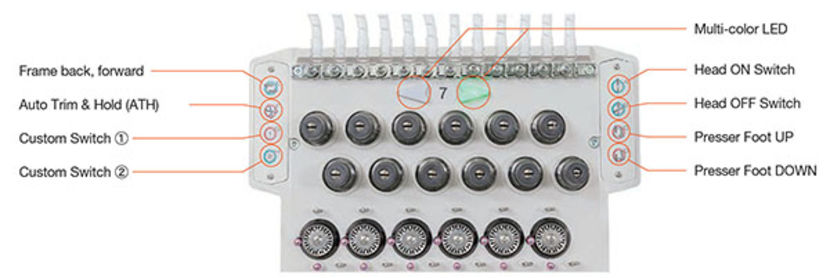

Several control keys and coloured LEDs have been placed on each head, thereby granting access to all of the main features: work efficiency is optimised for users and less movement is required.

Various optional tools and devices are available to enable the production of a large variety of articles:

- twin type or simple type sequin device,

- multi-cording device which enables embroidery with 6 types and/or different coloured cords,

- a position marker,

- an automatic lubrification system,

- a bobbin changer

- bobbin changer,

- beam sensor

- and LED lighting.

Different types of de frames can be fitted to this machine, depending on your needs:

- tubular frames of different types to match your articles (for embroidery on t-shirts, sweatshirts and jackets),

- the wide cap or semi-wide cap reinforced frame,

- a border frame for embroidering badges or appliqués,

- and the pocket frame.